Dimensional Weighing

In Motion Cubing & Dimensioning Systems

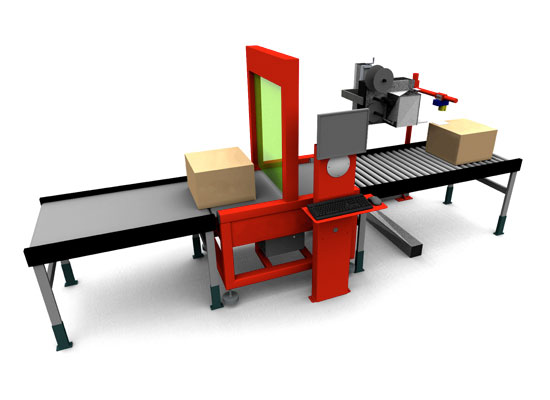

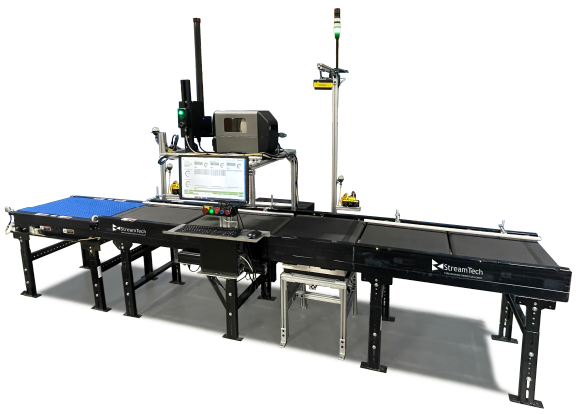

Dynamic or in-motion cubing systems are designed to provide real time package dimensions for packages processed on conveyors for inbound and outbound parcel processing. Our industrial grade design allows operations to incorporate dimensional weighing equipment or cubing scanner systems directly to their existing conveying system. For operations looking to increase throughput and reduce operating costs, we also provide turn key cubing systems for the automation of your shipping and manifest systems. These shipping and returns processing systems are easily integrated with existing processing equipment. The turn key Sprinter is a cost effective and scalable solution designed to meet and exceed your performance standards for accuracy and through-put. And, if your needs exceed the scope of the Sprinter, then we can work with our suppliers to create a custom high speed automation solution that meets your metrics.